We must improve the final temperature of carbonization and slower the speed of heating-up and cool down. Carbonization is the central part of making charcoal. This process makes the wood briquette into hydraulic briquetting machine which is popular among BBQ lovers.During the carbonization process, keeping the temperature at a constant degree is not correct.Because that the wood briquette need different temperature in the carbonization furnace.

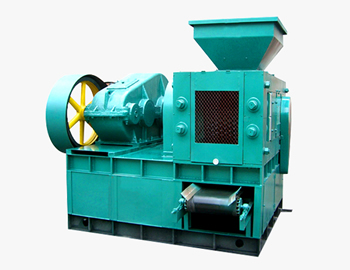

briquette machine' align='left'

width='300' />Today it is estimated that oil prices of more than$100 per

barrel are required in order to incentivize new exploration and production in

many prospective regions.And this must boost the prospects for renewable

energy.In the drying stage, the temperature is 160℃ and then in the initial

phase the temperature up to 160℃~280℃ and last in the carbonization stage the

temperature up to 300℃~600℃.So ,we must notice that not up or low the

temperature too fast because that will make the charcoal not stable and easy to

crack or break.On the contrary,the charcoal will have high density and

hardness.How to Operate hydraulic briquette

machine.

briquette machine' align='left'

width='300' />Today it is estimated that oil prices of more than$100 per

barrel are required in order to incentivize new exploration and production in

many prospective regions.And this must boost the prospects for renewable

energy.In the drying stage, the temperature is 160℃ and then in the initial

phase the temperature up to 160℃~280℃ and last in the carbonization stage the

temperature up to 300℃~600℃.So ,we must notice that not up or low the

temperature too fast because that will make the charcoal not stable and easy to

crack or break.On the contrary,the charcoal will have high density and

hardness.How to Operate hydraulic briquette

machine.

1, The first thing you need to do is collect some sugarcane bagasse. It doesn’t matter if the bagasse are smaller or larger in size. If you like, you can cut up them into smaller size.

2, Dry the sugarcane by direct sunlight to reduce moisture content from about 50% to less than 18% before being carbonized.This was important in saving on the cose of energy used during carbonization.And if the material is too wet, a dryer machine is needed.The area receives a great deal of sunshine every month, which is very conducive to the growth of sugarcane.Kenya generates about 1.6 million tones of sugarcane bagasse which has enormous potential for exploitation in modern commercial applications. And utilize that to produce charcoal briquette is a very feasible and profitable idea.

small briquetting machine: http://www.coal-briquettemachine.com/products/small-briquetting-machine.html

| 리버풀 이야기 축구 이야기 자유 게시판 포토 갤러리 축구 동영상 잘 부탁드립니다 | 최근 댓글 |